Sheet Metal Laser Cutting Services In The UK

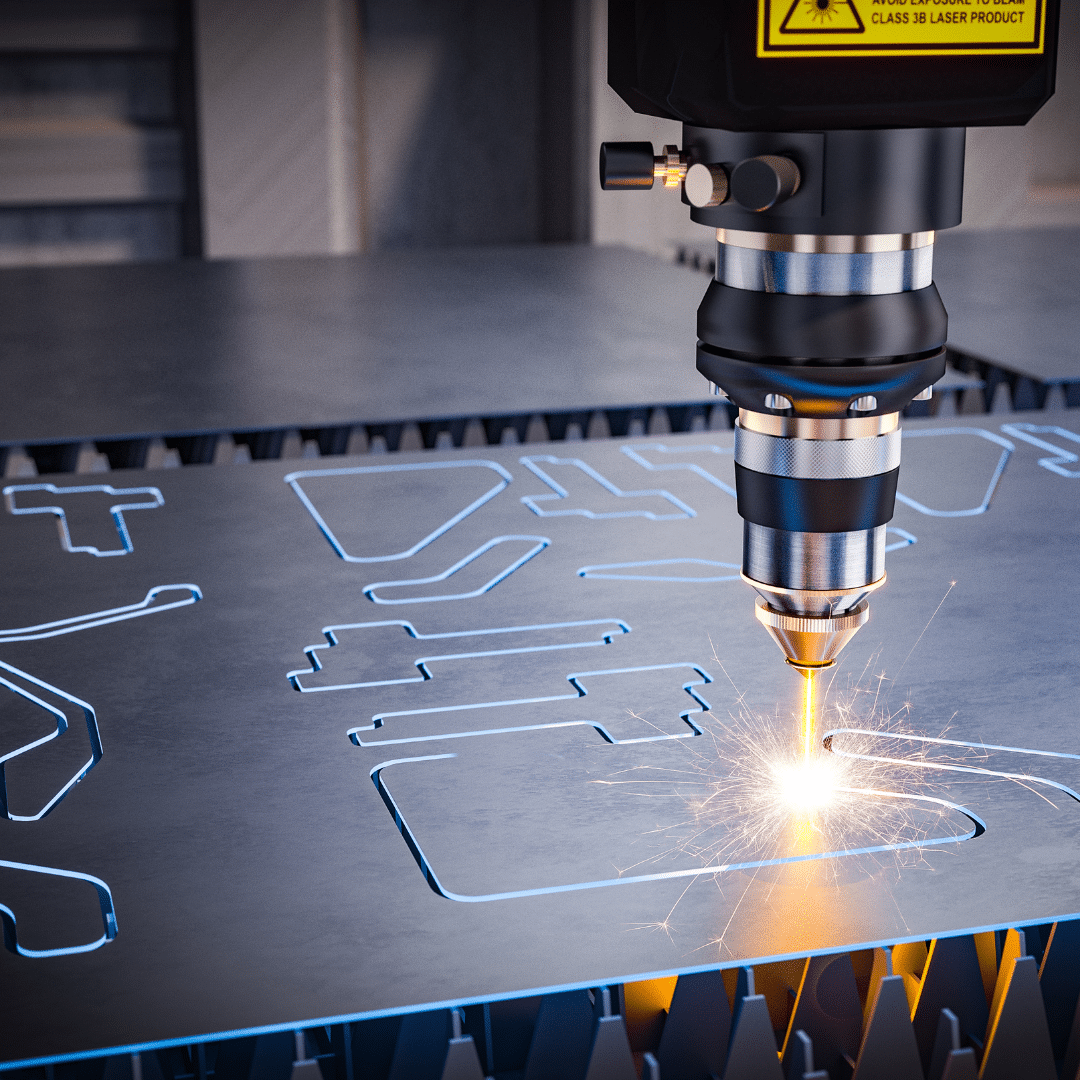

B.B. Price is proud to offer industry-leading laser cutting services to UK industries in need of precision-cut metal. Our state-of-the-art laser cutting machine is capable of cutting sheet metal up to 20mm thick.

Our system is renowned for both precision and quality of finish, allowing us to cut sheet metal with unerring accuracy.

What's more, our systems use a flying optic configuration, which allows us to precision-cut sheet metal at exceptional speed. This means shorter turnaround times and faster product delivery.

For expert laser cutting services in the UK, get in touch with the metal fabrication experts at B.B. Price today.

What is Laser Cutting?

Laser cutting is a technological process that uses lasers to cut through materials. It is a relatively new production technique compared to many operations in the manufacturing world. The first known example of laser cutting dates back to 1965. Vastly less powerful or accurate than the modern-day equivalents.

CNC (computer numerical control) and laser optics direct the laser beam into the correct place and to create the prescribed pattern out of the material. By focusing the laser beam, the material is either melted, burnt, vaporized or is blown away by a jet of gas. The thinnest part of a focused laser is typically less than 0.3mm.

A pierce/hole must be done before each cut in order to start cutting anywhere other than the edge of the sheet. This is usually done using a very strong, pulsed beam and may take a few seconds to make the first pierce.

Precision Technology at B.B. Price

Our brand-new facility in Cradley Heath is now home to one of the most advanced laser-cutting machines in the region. Our advanced system has been supplied by Amada; market-leaders in the laser cutting industry.

This means you can expect exceptionally cut or engraved sheet metal when you choose B.B. Price us for all your metal fabrication needs.

Here are few key technical features and capabilities of our cutting-edge laser system:

Capable of slicing through metals up to 20mm thick, the system handles everything from fine sheet work to heavy steel plates. This versatility ensures consistent results across a wide spectrum of materials and gauges.

Our flying optic design enables unrestricted movement across both vertical and horizontal axes. This allows the cutting head to navigate complex shapes efficiently without repositioning the material — ideal for producing large or intricate parts with speed and precision.

By combining our cutting-edge technology with computer numerical control (CNC), we can produce identical products across multiple components. This digital precision ensures consistency and repeatability, which is an essential feature for both small batches and large-scale production.

Using advanced optics, the focused beam achieves a kerf width of less than 0.3mm. This extreme accuracy minimises material waste and guarantees smooth, burr-free edges, even on complex geometries.

The laser system features a powerful pulsed mode for clean pierces, even away from material edges. It also supports deep engraving on thicker metals, enabling functional markings, part IDs, and decorative detailing directly into the surface.

Advantages of Laser Cutting In Metal Fabrication

There are many advantages to using laser cutting over shearing or plasma cutting in steel fabrication, including:

- Greater precision: A laser beam will not wear down with usage so there won’t be an uneven or warped cutting tool being applied against the material.

- Reduced risk of contamination: There isn’t a cutting edge that has been used to make other cuts which may have been contaminated with residue from previous jobs

- More economical: The process is drastically more automated than shearing so helps to save labour costs. In comparison to plasma cutting, the capital cost is much lower, and the running expenses are also lower due to a less powerful beam being required as laser cutting is not typically used on thicker material.

End-to-End Steel Laser Cutting Services UK

At B.B. Price, our laser cutting services form only one part of our broader steel fabrication services. We provide a complete solution for clients across a range of industries that includes:

-

Precision CNC Machining

-

Welding Services: Six welding and fabrication stations for assemblies up to 12 metres.

-

Metal Pressing: Cold and hot metal pressing machines delivering up to 1,000 tonnes of force.

-

In-House Toolmaking: This ensures complete control over production.

-

Shot-blasting & Galvanizing: We can impart sheet metal with a zinc coating for a durable, corrosion-resistant finish.

By offering all of the above in-house, we provide a complete, end-t-end steel fabrication solution for our clients. This ensures one-point of contact for full traceability, and full project management for consistent quality. Whether you require a one-off custom component or a high-volume production run, our team ensures your project is delivered on time and to specification.

Why Choose B.B. Price?

Steel & Sheet Metal Laser Cutting Services

Contact B.B. Price Today

So if you're in need of precision-cut steel metal, sheet metal, or another form of metal fabrication, get in touch with B.B. Price today.

Our industry-leading laser cutting services ensures we can meet the most exacting specifications with precision and accuracy.

As principle manufacturers for the rail and powerline industry, we're renowned for producing metal components with exceptional levels of quality and durability. Regardless of your industry or project scope, we have the capacity to handle it, with an unwavering commitment to quality and professionalism.

Find out more about how laser cutting can benefit you and what our team of laser cutting specialists can do to help you get the products that you need with ease.

B.B. Price offers laser cutting near me, including laser cutting Birmingham and across the UK.