Forging Vs Casting Vs Machining: Key Differences

Forging, casting and machining are all processes used in the manufacture of metal components and structures. These processes are typically performed by specialist metal-working companies who posses the necessary equipment to produce high-precision parts using age-old methods and techniques.

However, if you are in need of a precise metal part for a specific use, it is important to understand the differences between forging, casting and machining. This is because the properties of the metal parts produced will vary depending on the process chosen.

To ensure your metal component or structure will be fit for its intended purpose, selecting the right method is essential. In this blog, we'll breakdown what each process involves, how they differ from one another, and which option is right for your specific needs.

What Is Forging?

Forging is an age-old manufacturing method that has been around for centuries. Forging is the preferred choice for many industries because of its ability to produce extremely strong and durable metal components.

Forging involves applying extreme heat to pieces of metal to make them malleable (but not molten). Once the metal has been softened, compressive force is then applied to re-shape the metal into a desired form.

This force can be applied using hand tools to produce more precise parts. However, when it comes larger components, or those that need to be produced in bulk, hydraulic presses, hammers, and dies (also known as tools), are typically used instead.

When Is Forging Useful?

Forging is useful in industries where strength and durability is the top prioirty. This is because forging produces superior grain structure when compared to casting. It’s particularly ideal for high-stress parts that need to withstand impact, wear, and fatigue.

What Is Casting?

Casting on the other hand is a metalworking technique that involves heating metal until it melts and becomes molten, and so it differs significantly to forging, which only seeks to soften the metal.

Once the metal has become a liquid, it is then precisely poured into a mould, where it spreads out evenly. When the metal cools, it then solidifies into the exact shape of the mould, producing a precise metal component.

When Is Casting Useful?

Casting is useful for producing complex or intricate metal components that would take too long to produce by hand, or with forging presses and dies.

It’s ideal for producing more decorative or detailed components cost-effectively, especially if they are to be used in lower-stress applications. It also allows for greater design flexibility and is often the preferred choice for producing more aesthetic parts, rather than structural parts or components for critical applications.

However, casting typically results in inconsistent grain structures, leaving pockets of air or voids that makes cast metal parts less strong and durable when compared to forged parts.

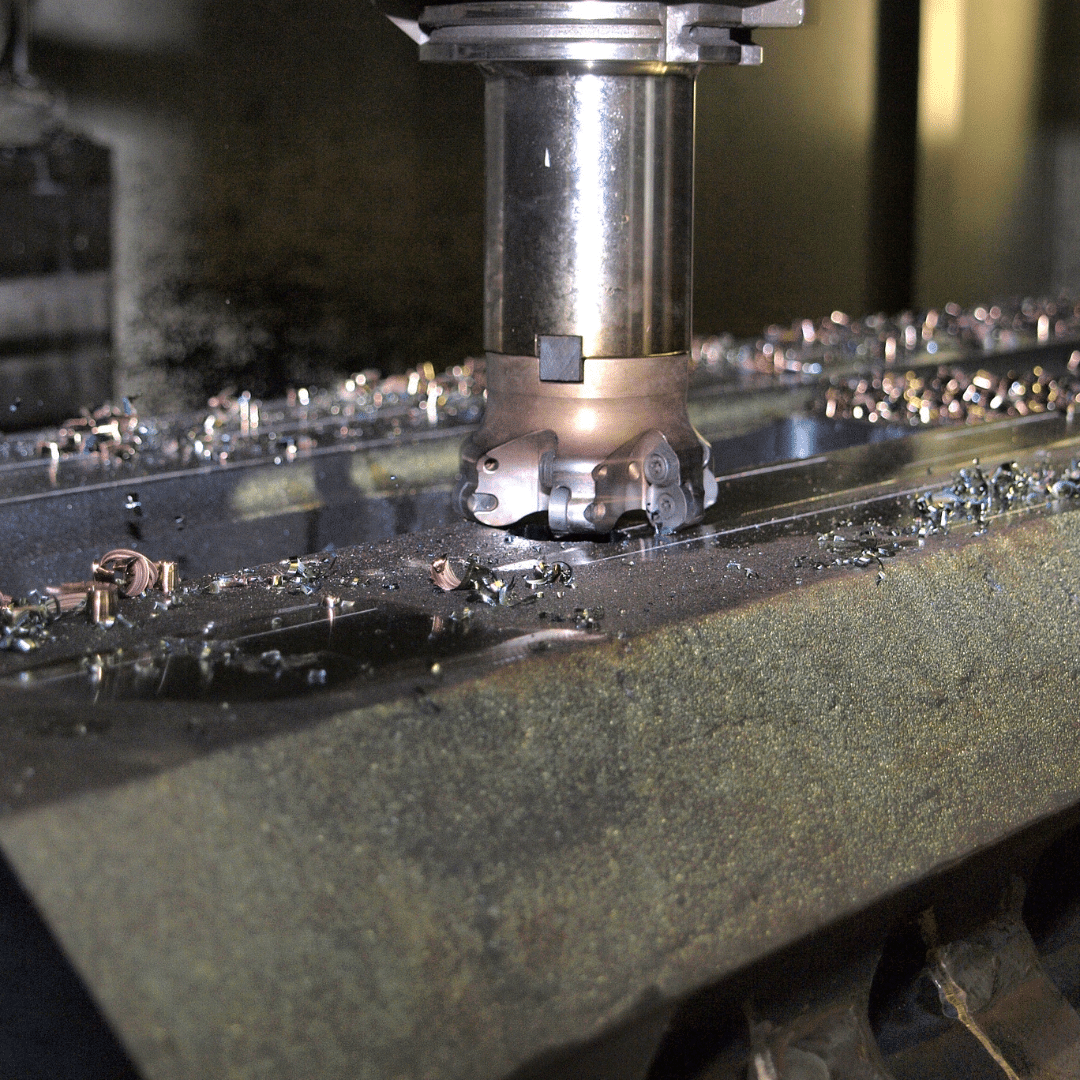

What Is Machining?

Machining differs from both forging and casting because it works with solid metal, rather than molten or softened metal. It works by removing material from a solid metal work-piece. It is therefore a subtractive manufacturing process, as it seeks to create the final shape by subtracting (cutting away) metal from an unfinished, solid work-piece.

Machining starts with raw material, often a solid block, or a piece that has just been forged which requires additional shaping. It uses a variety of cutting tools to sculpt the piece into a specific design.

It can be done manually, but in modern manufacturing, CNC (Computer Numerical Control) machines are used almost exclusively. This is because the software used in operating these machines allows for tools to be controlled with extreme precision, allowing for consistent and repeatable results.

When Is Machining Useful?

Machining works well across many materials and is often used when accuracy is more important than raw strength. It's ideal for producing high precision and tighter tolerances, making it useful if you want a particularly precise component.

It is particularly useful for refining metal parts that have already been cast or forged, if they still lack the precise detailing required

Forging Vs Casting Vs Machining: Key Differences

Feature |

Forging |

Casting |

Machining |

|---|---|---|---|

Strength |

Excellent | Moderate | Dependent on base material |

Material Waste |

Low | Medium | High |

Cost-Effectiveness |

Moderate (best for long runs) | High (best for short runs) | Moderate |

Precision |

Moderate | Moderate to High | High |

Complexity of Shape |

Moderate to High | High | High |

Ideal For |

Structural, high-stress parts | Decorative or complex-shaped

components |

Precision-finishing parts that have already been cast or forged |

Forging Vs Casting: Which Is Better?

Machining is often used in conjunction with forging and casting, rather than as a replacement. This means that often, the choice of which manufacturing process to opt for boils down to forging and casting, so understanding their distinct advantages and disadvantages is crucial for figuring out which process might be best for your project.

Key Advantages of Forging Over Casting

Forged metal components are commonly used in industries where strength and durability are crucial. This is because the forging process aligns the internal grain structure of the metal, leading to less pockets of air or voids. This makes the finished forged product far stronger and more resistant to fatigue than a cast part. Key advantages of forging include:

-

Superior Strength: Forging refines the grain structure, resulting in parts that are stronger and more fatigue-resistant than cast or machined equivalents.

-

Improved Durability: The aligned grain flow enhances impact resistance and toughness, making forged parts ideal for high-stress applications.

-

Consistency and Reliability: Forging produces uniform components with fewer internal defects like voids or porosity.

-

Material Efficiency: Unlike machining, which cuts away material, forging reshapes it, leading to less waste and better use of raw material.

-

Cost-Effective for Volume Production: Once tooling is in place, forging can be more economical for medium to high-volume production runs.

-

Versatile Applications: Suitable for everything from bespoke hand-forged components to high-volume industrial parts used in heavy or high-performance industries.

-

Better Grain Flow: Forged components maintain directional grain flow, which strengthens the part in the direction of use.

Drawbacks of Forging

However, forging does have its drawbacks:

-

Higher Initial Costs: Forging often requires specialised tooling and equipment, making it less cost-effective for very low-volume or prototype runs. Casting and machining may be more cost-effective here.

-

Limited Shape Complexity: Compared to casting, forging is less suited for highly intricate or hollow shapes without secondary machining, meaning its a slightly less flexible option.

-

Longer Lead Times: Processes like die creation and heat treatment can increase production time, especially for custom components. Casting and machining may yield faster production times depending on the parts required.

Key Advantages of Casting

Casting comes with a wide range of benefits, depending on the type of metal part required:

-

Complex Shapes: Allows for the creation of intricate geometries and hollow parts that are difficult or impossible to forge or machine.

-

Design Flexibility: Easily adapts to aesthetic or custom shapes, ideal for artistic or decorative applications.

-

Low Tooling Cost for Short Runs: Especially cost-effective for small production volumes or prototypes.

-

Wide Range of Sizes: Suitable for both small components and large, heavy parts.

-

Material Variety: Can use a wide range of metals and alloys, including those that are hard to forge.

-

Near-Net Shape: Produces parts close to the final shape, reducing the need for extensive machining or finishing.

-

Economical for Complex Parts: Lower manufacturing costs for parts that would require multiple machining or forging operations.

Drawbacks of Casting

However, casting comes with numerable drawbacks:

-

Lower Strength: Cast parts generally have inferior mechanical properties compared to forged ones due to internal porosity and weaker grain structure.

-

Higher Defect Risk: Susceptible to defects like cracks, shrinkage, and inclusions during cooling and solidification.

-

Limited Fatigue Resistance: Cast metals can fail under repeated stress, making them less suitable for high-stress applications.

-

Post-Processing Often Needed: Surfaces may require additional machining or finishing for tight tolerances and smoothness.

-

Longer Lead Times for Tooling: Creating molds can take time, especially for complex or custom designs.

Forging Vs Casting: Which is Better?

Process |

Advantages |

Disadvantages |

|---|---|---|

Forging |

- Exceptional strength and durability - Grain flow improves performance - Minimal internal defects - Low material usage - Ideal for high-stress applications |

- High initial tooling costs - Less suited for complex or hollow shapes - Longer setup and production time |

Casting |

- Can create very complex and detailed shapes - Ideal for large parts that need a specific shape - Suitable for a wide range of metals - Lower tooling cost for small batches |

- Weaker mechanical properties - More prone to porosity or shrinkage defects - Less dimensional accuracy |

Forging Vs Casting: Which Is Best For Me?

Choosing the right metal manufacturing process depends on what matters most to your business.

Forging is ideal for applications where strength, durability, and reliability are critical. It produces tough, long-lasting components perfect for high-stress environments and for applications where performance is critical.

Casting, on the other hand, is best for creating complex shapes or hollow parts where visual detail or form is more important than structural strength. It’s commonly used for pumps, housings, or decorative elements.

However, for most industries, forging is often the go-to solution. It's resistance to fatigue, strength, and long-lasting nature ultimately means that's it's the most dependable option for businesses who need reliable metal components and structures that will stand the test of time.

It’s especially suited for components that must endure constant force, wear, or environmental extremes, making it ideal for:

-

Rail, automotive, construction, oil & gas, energy, and defence sectors

-

Businesses that need components with maximum strength, reliability, and fatigue resistance

-

Businesses looking for long-term durability in safety-critical parts (e.g. couplings, brackets, or anchor points)

Forging and Machining: A Powerful Combination

At B.B. Price, machining is often the final step after our forging process. We might forge a component to get the basic shape and structure, maximising its strength and grain flow, before then machining it down to meet precise dimensions. This helps us to achieve the best of both worlds when it comes to the advantages of forging and machining.

This hybrid approach ensures:

-

The Strength and integrity found in forging techniques

-

The Precision finishing boasted by machining

Whether you're looking for bespoke one-off items or consistent, high-volume production, our in-house machining capabilities ensure the final product meets your exact specifications—right down to the last millimetre.

Contact B.B. Price For Expert Forged Parts Today

When strength, durability, and long-term performance are critical, forging is almost always the better choice. It’s the process that delivers robust components that can take a beating—perfect for sectors like construction, rail, telecommunications and defence.

At B.B. Price, we offer several types of forging:

-

Hand Forging: Often known as blacksmithing, this is the forging completed by hand, which is ideal for bespoke or smaller production runs

-

Drop Forging: This type of forging 'drops' hammers and dies onto the metalwork piece to create the compressive force required. This helps to produce high-strength parts quickly and precisely.

-

Upset Forging: This method uses a die to increase the diameter of metal components

At B.B. Price, we have over 50 years' experience in the art of forging. We don’t just forge steel; we forge reliability and performance into every product we deliver for our clients.

Still unsure which method would be best for your project? Get in touch with our team here at B.B. Price. Using the information you provide us, we'll be able to recommend a service tailored around your unique business needs, offering expert advice about which method would be best suited for your project.

Contact us today to speak to one of our specialists—we’re here to help shape your next project with an unwavering commitment to quality and professionalism.